How Carbon Fiber Sheets are Made: A Step-by-Step Process

Carbon Fiber Sheets are highly sought after for their exceptional strength, lightweight nature, and versatility. These properties make Carbon Fiber an ideal material for use in a wide variety of industries, including aerospace, automotive, sports equipment, and construction. But how exactly are Carbon fiber sheets made? In this article, we will walk you through the process of manufacturing carbon fiber sheets, from raw materials to finished products.

1. The Raw Material: Carbon Fiber Precursor

The manufacturing of carbon fiber sheets begins with the raw material known as the precursor. The most common precursor material is polyacrylonitrile (PAN), although other materials like pitch and rayon can also be used.

- PAN fibers are made by spinning the polymer into a fiber, which is then oxidized at high temperatures to convert it into carbon fiber. The fibers themselves are long, fine strands that are later woven or layered to create the sheets.

2. Spinning the Precursor into Fibers

Once the precursor material is ready, it is processed into fiber through a method known as spinning. This involves extruding the precursor through a spinneret (a type of nozzle) to form long, thin fibers. These fibers are then collected in large spools, ready for the next stage of production.

- Key factors in fiber spinning: The temperature, pressure, and speed during the spinning process can affect the quality and properties of the carbon fibers.

3. Stabilization Process

After the fibers are spun, they must go through a stabilization process, which involves heating the fibers in an oxidizing oven at temperatures ranging from 200°C to 300°C (392°F to 572°F). During this step, the fibers undergo a chemical transformation, cross-linking the polymer chains to make them stable and resistant to further processing.

- Why stabilization matters: This process prevents the fibers from burning during the subsequent carbonization process, ensuring that the carbon fiber maintains its strength and integrity.

4. Carbonization: Transforming to Carbon Fiber

The stabilized fibers then undergo carbonization, a critical step in the creation of carbon fiber. Carbonization involves heating the fibers to very high temperatures (typically 1000°C to 3000°C or 1832°F to 5432°F) in an inert environment, usually a furnace or a reactor that lacks oxygen.

- Carbonization process: At these extreme temperatures, the fibers undergo a process of dehydrogenation, and most of the non-carbon elements (such as oxygen, hydrogen, and nitrogen) are removed, leaving behind almost pure carbon.

- The result is highly oriented carbon atoms, giving the fiber its outstanding strength, rigidity, and high-temperature tolerance.

5. Surface Treatment

To improve the bonding capabilities of the carbon fibers, especially when used in composite materials like carbon fiber sheets, the fibers undergo a surface treatment. This step typically involves oxidizing the fiber surface to create chemical groups that enhance adhesion to resin or other matrices.

- Surface treatment methods: Techniques like plasma treatment or coating the fibers with an intermediate sizing layer help the fibers better bond with resins during the sheet-making process.

6. Weaving the Carbon Fiber

Once the carbon fibers have been created, they are woven or laid out into specific patterns to create fabric. The most common Weave patterns include:

- Plain weave: A simple over-and-under pattern.

- Twill weave: A more complex weave that creates a diagonal pattern and enhances the material's flexibility.

- Unidirectional weave: Fibers are aligned in one direction to provide maximum strength along that axis.

The carbon fibers are woven into sheets, creating a fabric that can be cut to the desired size for further processing.

7. Resin Impregnation: Creating a Composite

To create carbon fiber sheets, the woven carbon fiber fabric needs to be impregnated with a resin matrix. This is typically done using a process called prepregging, where the fabric is coated with a thermosetting resin, such as epoxy. The resin helps bond the fibers together, making the material easier to shape and mold while adding additional Strength and durability.

- Prepregging: The fabric is coated with resin and partially cured to create a pre-impregnated material that is easy to handle before it undergoes full curing.

8. Lay-Up and Molding

The resin-impregnated carbon fiber fabric is then laid up in layers, a process known as lay-up. The layers of fabric are stacked on top of each other in a mold to create the desired thickness and shape of the final carbon fiber sheet.

- Layering process: Each layer of carbon fiber fabric is oriented in a specific direction to achieve the required strength properties in different directions. This is particularly important in applications where multidirectional strength is needed.

- After the layers are laid up, the material is placed in a vacuum bag or autoclave to remove air and ensure proper resin distribution and adhesion.

9. Curing the Composite

The lay-up is then subjected to a curing process, where the resin is fully hardened or "cured" under controlled temperature and pressure. This step can take place in an autoclave (a large, high-pressure oven) or at room temperature, depending on the type of resin used.

- Autoclaving: This high-pressure and high-temperature process ensures the resin fully cures, bonding the carbon fibers together and creating a solid composite material. It also improves the overall mechanical properties of the carbon fiber sheet.

10. Cutting and Finishing

Once the curing process is complete, the carbon fiber sheet is carefully removed from the mold. At this stage, the sheet may still have rough edges or excess material that needs to be trimmed or machined.

- Finishing: The carbon fiber sheets are then cut to the desired size and shape using specialized equipment like laser cutters, water jets, or CNC machines. After cutting, the sheets may undergo polishing, sanding, or coating to achieve the final surface finish.

11. Inspection and Quality Control

Before the carbon fiber sheets are shipped out to customers, they go through a rigorous inspection process to ensure that they meet quality standards. This includes checking the thickness, resin content, and mechanical properties of the sheets. Any defects or inconsistencies are addressed at this stage to ensure the highest level of performance.

Conclusion

The production of carbon fiber sheets involves a complex and meticulous process, from the selection of raw materials to the final product. By combining advanced technologies, such as fiber weaving, resin impregnation, and curing, manufacturers create carbon fiber sheets that offer exceptional strength, lightweight performance, and durability for a wide range of applications. Whether you're using these sheets for aerospace components, automotive parts, or industrial machinery, the process ensures that every sheet is a high-performance material tailored to your needs.

At Carbon Fiber Global, we specialize in providing high-quality Carbon Fiber Solutions, including custom-made sheets, to meet the precise demands of our customers. If you're looking for carbon fiber sheets with unmatched strength and versatility, contact us today to learn more about our products and services.

- Line协议号注册器市场巅峰:我的LINE营销工具心得,让你事业一飞冲天

- 极空间私有云勇夺第一季度京东NAS网络存储行业双冠军

- Instagram自动化引流助手,ins高效私信软件,ig精准采集,ins协议号

- 独树一帜,创意精髓:WhatsApp拉群工具点亮你的推广创意之火

- ins强力引流神器来袭!Instagram群发营销软件,Ins客户引流不再愁!

- 不忘初心,奋楫千里 贸泽电子庆祝公司成立60周年

- 国产PET/CT,凭什么?

- 从“稳中求进”的发展新战略,看碧桂园服务的长期主义 碧桂园服务:以长期主义走出稳健增长曲线

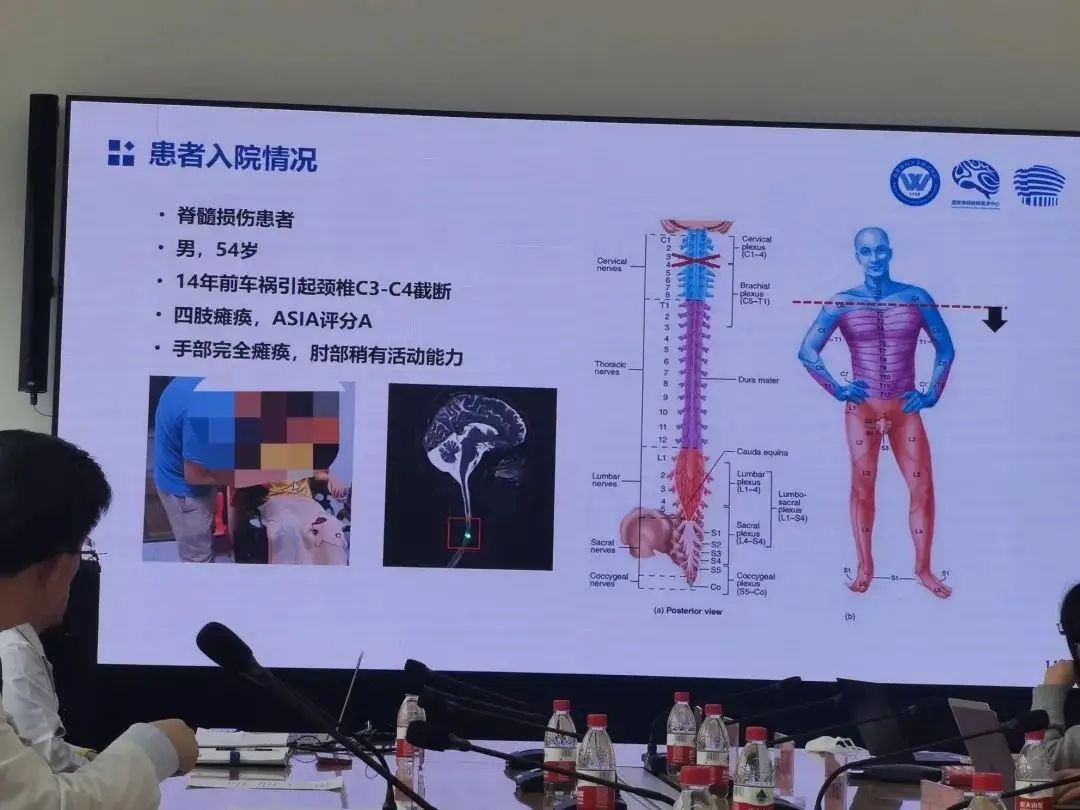

- 老杨第一次再度抓握住一瓶水,他由此产生了新的憧憬

- WhatsApp协议号注册器,智能推广工具,带您走向网络通信的新高度

- "全感官盛宴,尽在WhatsApp拉群工具

- Instagram群发营销工具,ins自动私信助手,ig引流利器

- Instagram引流推广助手,ins自动群发软件,ig私信采集

- WhatsApp一键筛选工具,ws高效自动过滤,ws精准群发软件,筛选利器

- Instagram最强群发工具,ins快速引粉营销软件,ig引流工具,ins群发引流工具

- 礼遇双十一,Liebherr利普赫尔以冷藏冷冻系列臻品实力开启“探鲜之旅”

- 进入元宇宙,体验令人惊叹的新东京 - The Virtual Edo-Tokyo Project (虚拟江户东京项目)

- 新体验·新增长丨班牛第五届智服未来大会在杭州圆满落幕!

- WhatsApp全球筛选神器,ws高级过滤,ws自动群发助手,精准引流

- Instagram批量养号工具,Ins自动登录软件,ig营销引流推荐

- WhatsApp拉群工具助力外贸新手 如何通过创意亮点蜕变成为营销领域的精英

- 穿越周期智能前行,火星人集成灶创新引领厨电行业新篇章

- “全自动WhatsApp批量拉群,就选我们的专业批量群发工具

- 揭秘湖南省康宸新材料有限公司全屋整装从容不改的精神境界

- 聚焦前沿技术,共筑智能未来 —— embedded world China上海国际嵌入式展六月即将开幕

- Ins打粉营销助手,Instagram群发工具,助你成就营销传奇!

- Instagram引粉工具,ins高效引流软件,ig全自动引流 +ins协议号

- XC7VX980T-L2FFG1930E: Revolutionizing FPGA Solutions for High-Performance Computing | ChipsX

- Instagram私信采集软件,ins群发信息工具,ig私信引流助手

- Instagram引流爆粉营销工具,Ins群发工具,带你实现营销逆袭!

推荐

-

苹果罕见大降价,华为的压力给到了?

1、苹果官网罕见大降价冲上热搜。原因是苹

科技

苹果罕见大降价,华为的压力给到了?

1、苹果官网罕见大降价冲上热搜。原因是苹

科技

-

升级的脉脉,正在以招聘业务铺开商业化版图

长久以来,求职信息流不对称、单向的信息传递

科技

升级的脉脉,正在以招聘业务铺开商业化版图

长久以来,求职信息流不对称、单向的信息传递

科技

-

丰田章男称未来依然需要内燃机 已经启动电动机新项目

尽管电动车在全球范围内持续崛起,但丰田章男

科技

丰田章男称未来依然需要内燃机 已经启动电动机新项目

尽管电动车在全球范围内持续崛起,但丰田章男

科技

-

老杨第一次再度抓握住一瓶水,他由此产生了新的憧憬

瘫痪十四年后,老杨第一次再度抓握住一瓶水,他

科技

老杨第一次再度抓握住一瓶水,他由此产生了新的憧憬

瘫痪十四年后,老杨第一次再度抓握住一瓶水,他

科技

-

B站更新决策机构名单:共有 29 名掌权管理者,包括陈睿、徐逸、李旎、樊欣等人

1 月 15 日消息,据界面新闻,B站上周发布内部

科技

B站更新决策机构名单:共有 29 名掌权管理者,包括陈睿、徐逸、李旎、樊欣等人

1 月 15 日消息,据界面新闻,B站上周发布内部

科技

-

全力打造中国“创业之都”名片,第十届中国创业者大会将在郑州召开

北京创业科创科技中心主办的第十届中国创业

科技

全力打造中国“创业之都”名片,第十届中国创业者大会将在郑州召开

北京创业科创科技中心主办的第十届中国创业

科技

-

如何经营一家好企业,需要具备什么要素特点

我们大多数人刚开始创办一家企业都遇到经营

科技

如何经营一家好企业,需要具备什么要素特点

我们大多数人刚开始创办一家企业都遇到经营

科技

-

智慧驱动 共创未来| 东芝硬盘创新数据存储技术

为期三天的第五届中国(昆明)南亚社会公共安

科技

智慧驱动 共创未来| 东芝硬盘创新数据存储技术

为期三天的第五届中国(昆明)南亚社会公共安

科技

-

疫情期间 这个品牌实现了疯狂扩张

记得第一次喝瑞幸,还是2017年底去北京出差的

科技

疫情期间 这个品牌实现了疯狂扩张

记得第一次喝瑞幸,还是2017年底去北京出差的

科技

-

创意驱动增长,Adobe护城河够深吗?

Adobe通过其Creative Cloud订阅捆绑包具有

科技

创意驱动增长,Adobe护城河够深吗?

Adobe通过其Creative Cloud订阅捆绑包具有

科技