A ‘Complete Revolution’ in Manufacturing: NTT DATA Research Reveals GenAI’s Transformative Potential

Despite clear opportunities to improve efficiency and bottom-line performance with GenAI, lack of usage policies and essential guardrails leave most manufacturers at risk

TOKYO & LONDON -- (BUSINESS WIRE) --

NTT DATA, a global leader in digital business and technology services, today introduced new data that shows manufacturing organizations worldwide are increasingly turning to GenAI to establish smart factories, spur innovation, improve productivity, build resilience and gain competitive advantage. The report – "Feet on the Floor, Eyes on AI: Do you have a plan or a problem?" – also uncovers significant challenges related to workforce and infrastructure readiness as well as ethical frameworks for governance.

The study surveyed more than 500 manufacturing leaders and decision makers in 34 countries. Key findings include:

- 95% of respondents said GenAI is already directly improving efficiency and bottom-line performance.

- 94% expect the integration of Internet of Things (i.e., IoT/edge) data into GenAI models will significantly improve the accuracy and relevance of AI-generated outputs.

- 91% say combining digital twins and GenAI will improve both physical asset performance and supply chain resilience.

- Respondents said their most frequent use cases are supply chain and inventory management; knowledge management; quality control; research and development; and process automation.

“AI is streamlining processes and redefining what’s possible across the entire manufacturing value chain, from supply chain predictions to quality control,” said Prasoon Saxena, Co-Lead, Products Industries, NTT DATA, Inc. “GenAI can help organizations achieve flexibility in fast-changing business environments, especially in the face of uncertain tariff policies worldwide.”

Challenges to Success

Satisfaction with AI initiatives has surged over the past year, yet manufacturers still face significant challenges that include:

- Infrastructure: 92% of manufacturers said old technologies hinder vital initiatives, but less than half have conducted a full infrastructure readiness assessment.

- Complementary technologies: 94% expect the integration of Internet of Things (i.e., IoT/edge) data into GenAI models will significantly improve the accuracy and relevance of AI-generated outputs, yet not all are confident in their ability to complete such integrations.

- Responsible frameworks: While ethical AI is on the radar, only 47% of manufacturing leaders strongly agree their organization follows a robust framework that balances risk with value creation.

- Workforce readiness: Two-thirds of manufacturers say their employees lack the necessary skills to use GenAI effectively, creating functional and operational disadvantages and risks.

- Data Management: Just 41% of manufacturers strongly agree they have enough data storage and processing capabilities to support their GenAI workload needs, which will limit success.

“The most successful manufacturing organizations have already integrated GenAI into essential operations,” Saxena said. “Companies failing to plan, deploy and govern GenAI strategically will not only have a problem, they may be planning to fail.”

Visit our website to learn more about NTT DATA’s AI services for manufacturing.

About NTT DATA

NTT DATA is a $30+ billion trusted global innovator of business and technology services. We serve 75% of the Fortune Global 100 and are committed to helping clients innovate, optimize and transform for long-term success. As a Global Top Employer, we have experts in more than 50 countries and a robust partner ecosystem of established and start-up companies. Our services include business and technology consulting, data and artificial intelligence, industry solutions, as well as the development, implementation and management of applications, infrastructure and connectivity. We are also one of the leading providers of digital and AI infrastructure in the world. NTT DATA is part of NTT Group, which invests over $3.6 billion each year in R&D to help organizations and society move confidently and sustainably into the digital future.

- 远程X7E-400纯电牵引车批量交付江苏大客户,高效助力港口绿色运输

- 第五届《中华罗氏春晚》新闻公告

- 资本寒冬中的热钱流向:越秀再度加码,携手保碧剑指工商业市场

- WS外贸成长日记:WhatsApp工具是我每一步成功的见证者

- instagram群发营销软件平台,ins一键自动私信软件

- 第三代抗衰食品药海天奇珍的研究 重庆新时代国医大师张人善作

- 以新经济模式 掌舵健康养老航向

- “共和国首席画师” 刘宇一:描绘良宵盛会 传递人民心声

- Parse推出GigaLab,将单细胞测序能力扩大到每年数十亿个细胞

- 中信银行太原分行以优质服务解客户燃眉之急

- 2025年春运启航 肯德基温暖相伴助力归家路

- 大健康创新科研人才抗癌中医——晏合桢

- 【旺城金燕】燕窝——大自然的馈赠,健康与美丽的选择

- 吉利银河星舰7 EM-i斩获中汽冬测“双料第一”

- Merck Invests More than € 300 Million in New Life Science Production Site in Korea

- 《行进中国大运河篇》圆满收官 郭品超讲述运河精神展文化自信

- 涓子再演《上错花轿嫁对郎》延续经典 新版《花轿喜事》角色反差大

- 东莞信特佳:引领滚筒制造技术新潮流

- 临商银行商城小微支行党支部开展“重温工运历史·弘扬沂蒙精神·凝聚奋进力量”主题党日活动

- PCB设计自学好还是报个班好一点,能找到工作吗?

- Descartes Solution Streamlines Air Shipment Data Exchange with IATA’s ONE Record

- 瓜子二手车新能源消费观察:北方爱混动 南方爱纯电

- 刘诗诗《掌心》上星达成上星率100%,勇于突破客串张艺谋新作《惊蛰无声》

- 我和我的祖国读书会徽标发布:培育新质生产力,对话未来设计方向和使命

- 鹏特资本进入中国市场具有以下一些优势

- 北京汽車公佈二零二四年中期業績 深入落地「國內、國際」雙戰略 研發進階高質量發展向好

- 敏宝妈妈标杆之选,2024年顺峰宝宝再度斩获宝宝树金树奖!

- 杨洋官宣欧珑品牌代言人 探寻傲然于凛冬的无畏之息

- 王家渡独创爆珠烤肠,肉果CP,燃爆味蕾

- 戮力同心开新局,努力争当弄潮儿——《龙行盛世》主题展开幕

推荐

-

大家一起关注新疆乌什7.1级地震救援见闻

看到热气腾腾的抓饭马上就要出锅、村里大家

资讯

大家一起关注新疆乌什7.1级地震救援见闻

看到热气腾腾的抓饭马上就要出锅、村里大家

资讯

-

中国减排方案比西方更有优势

如今,人为造成的全球变暖是每个人都关注的问

资讯

中国减排方案比西方更有优势

如今,人为造成的全球变暖是每个人都关注的问

资讯

-

周星驰新片《少林女足》在台湾省举办海选,吸引了不少素人和足球爱好者前来参加

周星驰新片《少林女足》在台湾省举办海选,吸

资讯

周星驰新片《少林女足》在台湾省举办海选,吸引了不少素人和足球爱好者前来参加

周星驰新片《少林女足》在台湾省举办海选,吸

资讯

-

海南大学生返校机票贵 有什么好的解决办法吗?

近日,有网友在“人民网领导留言板&rdqu

资讯

海南大学生返校机票贵 有什么好的解决办法吗?

近日,有网友在“人民网领导留言板&rdqu

资讯

-

王自如被强制执行3383万

据中国执行信息公开网消息,近期,王自如新增一

资讯

王自如被强制执行3383万

据中国执行信息公开网消息,近期,王自如新增一

资讯

-

透过数据看城乡居民医保“含金量” 缴费标准是否合理?

记者从国家医保局了解到,近期,全国大部分地区

资讯

透过数据看城乡居民医保“含金量” 缴费标准是否合理?

记者从国家医保局了解到,近期,全国大部分地区

资讯

-

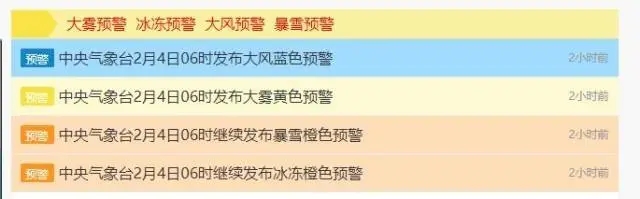

中央气象台连发四则气象灾害预警

暴雪橙色预警+冰冻橙色预警+大雾黄色预警+

资讯

中央气象台连发四则气象灾害预警

暴雪橙色预警+冰冻橙色预警+大雾黄色预警+

资讯

-

私域反哺公域一周带火一家店!

三四线城市奶茶品牌茶尖尖两年时间做到GMV

资讯

私域反哺公域一周带火一家店!

三四线城市奶茶品牌茶尖尖两年时间做到GMV

资讯

-

新增供热能力3200万平方米 新疆最大热电联产项目开工

昨天(26日),新疆最大的热电联产项目—&md

资讯

新增供热能力3200万平方米 新疆最大热电联产项目开工

昨天(26日),新疆最大的热电联产项目—&md

资讯

-

奥运冠军刘翔更新社交账号晒出近照 时隔473天更新动态!

2月20日凌晨2点,奥运冠军刘翔更新社交账号晒

资讯

奥运冠军刘翔更新社交账号晒出近照 时隔473天更新动态!

2月20日凌晨2点,奥运冠军刘翔更新社交账号晒

资讯