Unplanned Downtime Costs Manufacturers Up to $852M Weekly, Exposing Critical Vulnerabilities in Indu

Fluke data reveals 61 percent of manufacturers hit in the past year; outages stretch up to 72 hours and threaten profitability at the board level.

Everett, Washington, Oct. 30, 2025 (GLOBE NEWSWIRE) -- Fluke Corporation today released survey findings, exposing the true cost of downtime in industrial manufacturing. The findings reveal a silent crisis: more than six in ten (61 percent) manufacturers suffered unplanned downtime in the past year, costing the sector up to $852 million every week, capital the industry cannot afford to lose. Downtime is not only frequent and prolonged, but also reflects vulnerabilities that threaten profitability, competitiveness, and board-level resilience.

- Nearly half (48%) report 6–10 downtime incidents weekly; almost one in five (19%) face 11–20 incidents weekly.

- 45% say outages last up to 12 hours; 15% report incidents stretching to 72 hours.

- At an average cost of $1.7M per hour, a single incident can equal up to $42.6M in losses: the equivalent of powering 2,500 factories for a week.

The research, conducted by Censuswide, surveyed over 600 senior decision-makers and maintenance professionals in the U.S., the UK, and Germany. Among those affected, frequency is alarming: 48 percent report 6–10 incidents each week, and nearly one in five (19 percent) face 11–20 weekly incidents. The impact is then compounded by duration, with 45 percent of respondents saying outages last up to 12 hours, while a further 15 percent experience incidents up to 72 hours.

At an average cost of $1.7M per hour, a single incident can reach up to $42.6 M in losses: the energy equivalent of powering 2,500 average manufacturing facilities for a week, or a single factory for nearly 50 years. These findings indicate that downtime is a recurring operational reality and a board-level risk to profitability and resilience.

On a global level, the risks are more acute within large enterprises, among organizations with more than 50,000 employees, 40 percent report experiencing 11–20 downtime incidents each week, and half (50 percent) endure up to 72 hours per incident.

Despite the scale of the risk, the industry remains fragmented in its response to it. The findings show that Manufacturers are scattering digital investments across multiple solutions to build resilience, including predictive maintenance (12 percent), digital twins (12 percent), and condition monitoring (13 percent).

Parker Burke, Group President of Fluke Corporation, said: “Our research shows a tough reality: too many manufacturers are stuck reacting to downtime instead of getting ahead of it. Quick fixes might keep things running for a while, but they don't build long-term resilience.

“The data shows us that downtime can't be viewed just as operational problem anymore. It's a real risk to competitiveness and enterprise value.

He concluded, “Without a clear plan to scale digital investments, efforts are spread too thin to make a lasting, measurable impact. It's time to bring reliability into the boardroom as a core part of how we drive growth, performance, and customer trust.”

The survey, conducted by Censuswide on behalf of Fluke, surveyed 600 respondents representing manufacturing firms across the Food & Beverage, Oil & Gas, Life Sciences, and Automotive industries operating in Germany, the UK, and the US.

Weekly losses were estimated using average figures for outage time, cost, and frequency based on respondent data across different impact scenarios.

About Fluke

Founded in 1948, Fluke Corporation is the world leader in compact, professional electronic test tools and software for measuring and condition monitoring. Fluke customers are technicians, engineers, electricians, maintenance managers, and metrologists who install, troubleshoot, and maintain industrial, electrical, and electronic equipment and calibration processes. FLUKE is a registered trademark of Fluke Corporation. For more information, visit the Fluke website.

Contact:

Georgia Marchant

Fluke Corporation

georgia.marchant@fluke.com

Olivia Kline

Fluke Corporation

olivia.kline@fluke.com

- 链接全球 囍至广交丨双喜电器亮相第135届广交会二期

- 法国娇兰 一千零一夜世纪精粹淡香精(绚丽狂欢典藏版)

- 73 Thailand Companies Tackle Talent Crisis With Innovation, Flexibility, and Tech

- 体验美食便捷之选 外卖满足多样需求

- eXp Realty 首次推出联合推荐计划,推动经纪人协同发展新格局

- 中国人寿财险怀化市中心支公司开展 “情暖八一 镌刻惠军荣光” 退役老兵慰问活动

- 重磅!贝特佳荣膺首批“低GI食品团标”认证,系唯一入选的羊奶粉品牌

- Arthur D. Little and Mathlabs Announce Strategic Partnership to Improve Open Innovation Outcomes Usi

- 赵传北京演唱会致敬崔健 摇滚京剧混搭诠释“中国摇滚”

- Align Partners敦促改善Coway Co., Ltd.的治理和资本配置

- 2025广州白鹅潭春节烟花汇演圆满落幕 碳中和焰火产品点亮绿色夜空

- 人人敬重的“Xu Hong”老板——瑞芳茶号创始人江泰源

- Novotech 发布精准肿瘤学格局白皮书,指出靶向治疗的当前趋势和机遇

- 元宵暖意浓,情满加油站

- 回溯传奇香源,再续非凡情缘 法国娇兰携手法国驻上海总领事馆展开“非凡对话”

- 罗技发布灵砚系列客制化机械键盘,开启办公与娱乐新体验

- 金诃山健:传承千年藏医智慧 领航大健康产业创新之路

- GIGABYTE参展COMPUTEX 2025:以全面的基础架构与计算解决方案加速人工智能未来

- 九兴二零二四年纯利增21% 再次超额达成三年规划目标

- 农发行衡阳市分行专题研讨中央一号文件谋划服务乡村振兴新举措

- 九章云极DataCanvas公司入选北京市通用人工智能产业创新伙伴计划

- Nufarm and ChrysaLabs partner to address barriers in carbon innovation measurement for sustainable a

- 匠心铸金工•比武砺尖峰丨2025大金空调技能比武大赛正式启动

- NTT DATA和Kinaxis合作实现供应链现代化转型

- 75载无界担当丨携手央视网,国寿寿险重磅上线主题宣传片

- 仓储物流新概念,南京金棠仓储设备制造有限公司领航行业创

- Liebherr利普赫尔电器:传承与科技相融,智启健康保鲜新境界

- FPT Software Rallies Global Effort with Environmental Campaigns and Community Outreach

- CGTN: China's silver screen pivot: Why U.S. tariff policy is to blame

- EcoOnline庆祝与Menzies Aviation的长期合作伙伴关系,推动全球安全文化建设

推荐

-

看新东方创始人俞敏洪如何回应董宇辉新号分流的?

(来源:中国证券报)

东方甄选净利润大幅下滑

资讯

看新东方创始人俞敏洪如何回应董宇辉新号分流的?

(来源:中国证券报)

东方甄选净利润大幅下滑

资讯

-

大家一起关注新疆乌什7.1级地震救援见闻

看到热气腾腾的抓饭马上就要出锅、村里大家

资讯

大家一起关注新疆乌什7.1级地震救援见闻

看到热气腾腾的抓饭马上就要出锅、村里大家

资讯

-

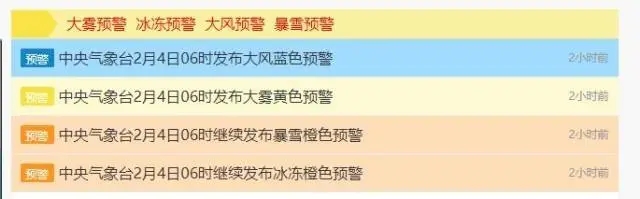

中央气象台连发四则气象灾害预警

暴雪橙色预警+冰冻橙色预警+大雾黄色预警+

资讯

中央气象台连发四则气象灾害预警

暴雪橙色预警+冰冻橙色预警+大雾黄色预警+

资讯

-

国足13次出战亚洲杯首次小组赛0进球

北京时间1月23日消息,2023亚洲杯小组

资讯

国足13次出战亚洲杯首次小组赛0进球

北京时间1月23日消息,2023亚洲杯小组

资讯

-

海南大学生返校机票贵 有什么好的解决办法吗?

近日,有网友在“人民网领导留言板&rdqu

资讯

海南大学生返校机票贵 有什么好的解决办法吗?

近日,有网友在“人民网领导留言板&rdqu

资讯

-

一个“江浙沪人家的孩子已经不卷学习了”的新闻引发议论纷纷

星标★

来源:桌子的生活观(ID:zzdshg)

没

资讯

一个“江浙沪人家的孩子已经不卷学习了”的新闻引发议论纷纷

星标★

来源:桌子的生活观(ID:zzdshg)

没

资讯

-

奥运冠军刘翔更新社交账号晒出近照 时隔473天更新动态!

2月20日凌晨2点,奥运冠军刘翔更新社交账号晒

资讯

奥运冠军刘翔更新社交账号晒出近照 时隔473天更新动态!

2月20日凌晨2点,奥运冠军刘翔更新社交账号晒

资讯

-

男子“机闹”后航班取消,同机旅客准备集体起诉

1月4日,一男子大闹飞机致航班取消的新闻登上

资讯

男子“机闹”后航班取消,同机旅客准备集体起诉

1月4日,一男子大闹飞机致航班取消的新闻登上

资讯

-

透过数据看城乡居民医保“含金量” 缴费标准是否合理?

记者从国家医保局了解到,近期,全国大部分地区

资讯

透过数据看城乡居民医保“含金量” 缴费标准是否合理?

记者从国家医保局了解到,近期,全国大部分地区

资讯

-

王自如被强制执行3383万

据中国执行信息公开网消息,近期,王自如新增一

资讯

王自如被强制执行3383万

据中国执行信息公开网消息,近期,王自如新增一

资讯