From Wind Tunnels to Space: Vacuum for Aerospace Research

MAULBURG, Germany - At the German Aerospace Center (DLR) in Göttingen, scientists are exploring the phenomena of compressible flow mechanics in Europe’s largest and most powerful tube wind tunnel using a COBRA screw vacuum pump from Busch Vacuum Solutions. The goal is to make the aerospace of tomorrow safer and more efficient.

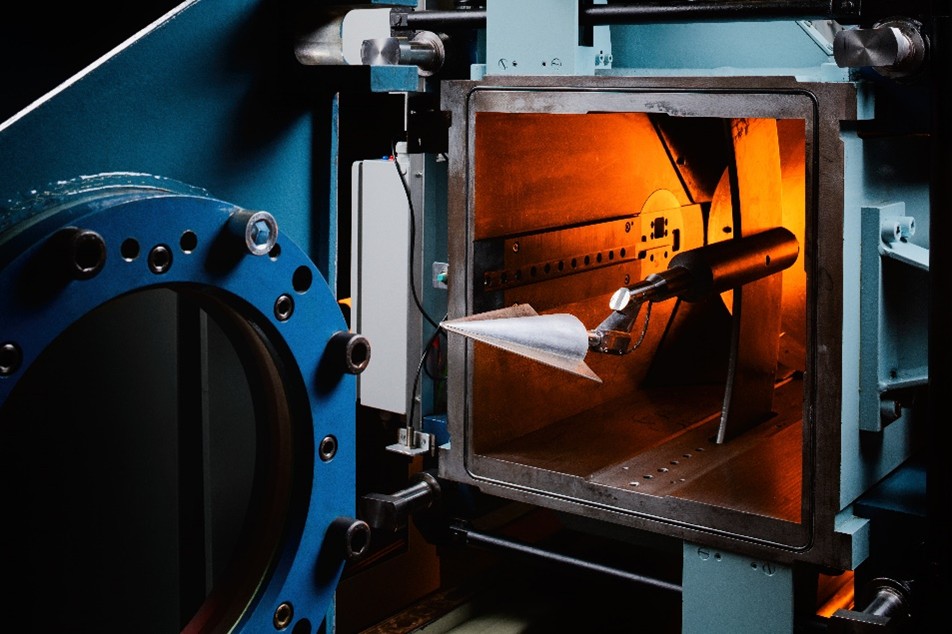

The German Aerospace Center (DLR) in Göttingen is researching fluid mechanics phenomena, which are essential for adequately predicting the performance of supersonic aircraft. Source: DLR.

Two accumulator tubes of more than 80 meters in length run over an open space next to the building and pass through the solid outer wall to the inside: The enormous dimensions of the research facility become clear as soon as you enter the site around the Institute of Aerodynamics and Flow Technology at the DLR in Göttingen. Inside, a giant vacuum vessel with a volume of 50 m³ is connected to the tubes. Detailed and fundamental studies are carried out there to investigate the fluid mechanics phenomena that are essential for adequately predicting the performance of supersonic aircraft. How can the aerospace vehicles of tomorrow become more environmentally friendly, safer and more efficient? And how can you use precise computer simulation of supersonic flight to evaluate new configurations while still in the design process? The scientists want to provide answers to these questions, and many others, with the tube wind tunnel. Vacuum technology from Busch is an indispensable part of these research projects.

The large-scale research facility was opened in the 1950s. Göttingen-based physicist and flow researcher Prof. Hubert Ludwieg developed a revolutionary drive system for intermittently operating high-speed wind tunnels, which enabled studies with supersonic and hypersonic flows to be carried out. He called this principle a tube wind tunnel – which to this day is also known around the world as a “Ludwieg tube.” In 1968, the Ludwieg Tube Wind Tunnel, Göttingen (RWG) was the first of these large-scale aerodynamic research plants in the world to be put into operation. It is still in use at the DLR to this day.

Experiments at supersonic speed

The operating principle of the tube wind tunnel uses the interaction of pressure and vacuum, where the accumulator tubes serve as pressure vessels in which the air is compressed. To prevent air condensation in the ultrasonic nozzle, which occurs due to the strong expansion and the associated cooling of the air, the accumulator tubes must be heated to simulate high supersonic velocities.

The accumulator tubes are connected to the ultrasonic nozzle via a quick-action slide valve. The measuring section is found at the end. This is where experiments are carried out. At the end of the measuring section is the vacuum vessel, which the vacuum pump is connected to. A vacuum slide valve between the measuring section and the vacuum vessel enables access to the measuring section as required. The vacuum vessel is evacuated using the vacuum pump. A COBRA NX screw vacuum pump from Busch Vacuum Solutions is used for this. It generates vacuum of approximately 10 to 40 mbar in the vacuum vessel. In the accumulator tubes, there is overpressure of approximately 2 to 40 bar.

To perform a test, the test model is placed in the measuring section using a movable model holder. Test models include aircraft models, sensors or material samples. Opening the quick-slide valve creates a running dilution wave that flows into the accumulator tube and accelerates the accumulator air towards the nozzle. Due to the differential pressure between the accumulator tube and the vacuum vessel, and thanks to the specially shaped ultrasonic nozzle, an ultrasonic flow is created in the RWG measuring section. Speeds of up to Mach 7 can be achieved – corresponding to seven times the speed of sound. Measurement times of up to 350–400 milliseconds are realized in the RWG. This is a peak value for wind tunnels of this type and gives researchers enough time to study the flow around the test models. During this time period, statistically relevant data or image sequences can be recorded to enable reliable data averaging and analysis.

More efficient testing thanks to vacuum

Vacuum technology is important not only for accelerating, but also for slowing down the high flow velocity. The air from the accumulator tube is collected in the vacuum vessel during the test and then discharged outside as normal ambient air. Dr. Erich Schülein, Group Leader and Scientific Supervisor of the RWG at the Institute of Aerodynamics and Flow Technology, explains: "Thanks to vacuum technology, we can carry out the tests much more efficiently. Without it, we would not only have to significantly increase the boost pressure in the accumulator tube, but also the requirements for the stability of the entire system and the testing technology in order to achieve the required pressure ratio in the ultrasonic nozzle at all. The technical effort required for this would be enormous. The vacuum pump does this work for us. The combined application of pressure and vacuum accumulators makes it easy to change the pressure level and thus the Reynolds number of the flow."

The tube wind tunnel in Göttingen has been in use since 1968 together with an old rotary vane vacuum pump. In 2021, it was high time to replace it. Busch was able to win the contract as part of a tender. The company’s experts then provided support with their expertise in selecting and dimensioning the system to find a suitable solution. A solution was quickly found with the dry COBRA NX.

Karsten Pfeiffer, Technical Manager of the RWG, explains: "For us, it is crucial that the vacuum pump used works reliably, because the flow generated in the tube wind tunnel must be clean. The tests are often carried out several times, and it is important that the conditions are reproducible at all times – which is why nothing should interfere with the flow." The performance of the COBRA also made a very positive impression. Compared to the previous rotary vane pump, the Busch screw vacuum pump evacuates the vacuum vessel twice as fast. The most commonly required pressure of 50 mbar in the vessel is now reached after just 15 minutes instead of half an hour. These shorter run times have a very positive effect on the energy consumption of the plant. In addition, a frequency converter adapts the vacuum pump's rotational speed to the required pressure conditions.

The institute’s employees are also pleased with the new vacuum solution. Previously, they were unable to use the working rooms directly above the plant during the tests due to the high noise level and vibrations generated by the old vacuum pump. With the COBRA, this is no longer a problem, as it operates very quietly and with low vibration. "You can't hear anything except a slight buzz," laughs Pfeiffer. Another major benefit is oil-free operation. "In the past, I had to do hands-on work regularly and change the oil – and then also change my resulting dirty clothes. This is no longer necessary. Maintenance is carried out by a Busch service technician as part of a maintenance contract. All I have to do is switch on the pump and it starts running," says Pfeiffer happily. Above all, the proximity of Busch to customers is a key benefit. Thanks to the company's extensive service network, the local contact person can be on site very quickly when needed.

Clean vacuum for technological progress

The reliable vacuum solution from Busch plays a key role in the success of the experiments in the RWG and supports technological progress. The DLR makes the results of its basic research available to companies in the aerospace industry to develop and refine technologies for current and future missions. The Göttingen-based scientists also work closely with international organizations such as NASA, ESA and the other DLR sites on global research projects. In the past, for example, a model of the X-38 spacecraft was tested in the Göttingen Ludwieg Tube Wind Tunnel on behalf of NASA and ESA. This craft was intended as a crew return vehicle (CRV) to be able to bring ISS astronauts back to Earth in the event of an emergency. This type of spacecraft must withstand enormous heat and mechanical loads when entering the Earth’s atmosphere. These conditions were replicated as accurately as possible in the tube wind tunnel .

"Despite enormous advances in numerical flow mechanics, many phenomena in turbulent flows still cannot be adequately and accurately predicted. In our studies, we create an important validation database that helps improve existing models and develop new numerical calculation methods. We see this as the actual purpose of this research facility," says Schülein. Vacuum technology from Busch is an important part of this.

About the Busch Group

The Busch Group is one of the world’s largest manufacturers of vacuum pumps, vacuum systems, blowers, compressors and gas abatement systems. Under its umbrella, the group houses two well-known brands: Busch Vacuum Solutions and Pfeiffer Vacuum+Fab Solutions. The gas abatement systems previously offered by centrotherm clean solutions – a former Busch Group brand – are now part of the Pfeiffer portfolio.

The extensive product and service offer includes solutions for vacuum, overpressure and abatement applications in all industries, such as food, semiconductors, analytics, chemicals and plastics. This also includes the design and construction of tailor-made vacuum systems and a worldwide service network.

The Busch Group is a family business that is managed by the Busch family. More than 8,000 employees in 44 countries worldwide work for the group. Busch is headquartered in Maulburg, Baden-Württemberg, in the tri-country region of Germany, France and Switzerland.

The Busch Group manufactures in its 23 own production plants in China, the Czech Republic, France, Germany, India, Romania, South Korea, Switzerland, the United Kingdom, the USA and Vietnam.

The Busch Group has an annual consolidated revenue of close to 2 billion Euro.

Press contact

Dr. Fabian Fahlbusch

Head of Content and Communications

Busch Vacuum Solutions

Schauinslandstrasse 1

79689 Maulburg, Germany

+49 (0)7622 681 - 3379

fabian.fahlbusch@busch.de

www.buschvacuum.com

www.buschgroup.com

- 眼睛里的“镜头”模糊了?爱尔英智眼科丁雪为您科普白内障的发生与治疗

- EB5排期4月狂退905天的底层原因,越港资本7期CMR梦想庄园EB5升级3重机制打破困局

- 光谷康服是家什么公司

- 从“血糖监测”到“控糖减脂”:硅基动感助力数智化健康管理

- 杭州中信养老与杭州市第一人民医院联手,共建医养新标杆

- 森赫电梯旗下高端子品牌圣爱美赫 · 火热招商中

- 软通动力助力打造“北京智造”标杆集群

- C.K. McWhorter Endows Maison Goyard With Esteemed McWhorter Family Trust Warrant Of Excellence

- Explore Future Technologies with ChipsX at IPC APEX EXPO 2024!

- 碧波逐梦,泳动千岛湖 | 2024千岛湖公开水域游泳公开赛圆满落幕!

- 仁术精诚 医道本源——周文军与新时代中医的新范式

- 海能达参与第九届MCX Plugtests并验证其一站式MCX解决方案互操作性

- 缦合•北京携手摩卡定制呈现“溯”—首届大型园林人生庆典秀

- Bitget CEO Gracy Chen Featured in Coindesk's Top 50 Women in Web3 and AI

- 加来众科WL8无线直播云声卡:让普通人被听见,小微个体也能“声”动世界

- 徐志贤《破茧2》开播 再演警察险象环生苏感拉满

- 瑞沃全球首发款智能感应分配器,自适应·多场景·数智化,重新定义用纸体验!

- 兴业银行香港分行成功晋级CIPS直参行 开启跨境人民币服务新篇章

- Australia's Rangebank Battery Energy Storage System, Victoria's second largest battery, is

- 冠科生物苏州实验室斩获CLIA认证 2025年双证落地夯实临床前服务能力

- Kai Tak Sports Park Limited和ASM Global为有史以来全球最大的体育发展项目的揭幕开始倒计时活动

- 创维光伏工商业“E企發”以更快更好更可靠的标准化模式,再一次引领行业!

- 盗龄医生AI万炁堂:万百万博士携手诺奖得主兰迪·谢克曼 带领万众实现健康财富双赢

- SS&C Technologies将收购Calastone

- 申晨实战派操盘手受邀分享《熊猫罗盘》,破解餐饮增长难题

- 重庆病人出院转院选择正规润兴救护车转运服务机构

- 第52届医疗器械博览会盛装启幕,开启AI 赋能驱动医疗装备“新视界”

- CIFF广州 | 设计公司逐浪国际潮流,红利如何收割?3月20日「世界设计峰会」20+国际嘉宾献计献策!

- Julius Meinl小红帽咖啡,以顺滑的口感征服了咖啡爱好者的味蕾

- 徐子清‖大雅正声--当代中国画学术中坚六十家提名展

推荐

-

透过数据看城乡居民医保“含金量” 缴费标准是否合理?

记者从国家医保局了解到,近期,全国大部分地区

资讯

透过数据看城乡居民医保“含金量” 缴费标准是否合理?

记者从国家医保局了解到,近期,全国大部分地区

资讯

-

一个“江浙沪人家的孩子已经不卷学习了”的新闻引发议论纷纷

星标★

来源:桌子的生活观(ID:zzdshg)

没

资讯

一个“江浙沪人家的孩子已经不卷学习了”的新闻引发议论纷纷

星标★

来源:桌子的生活观(ID:zzdshg)

没

资讯

-

国足13次出战亚洲杯首次小组赛0进球

北京时间1月23日消息,2023亚洲杯小组

资讯

国足13次出战亚洲杯首次小组赛0进球

北京时间1月23日消息,2023亚洲杯小组

资讯

-

看新东方创始人俞敏洪如何回应董宇辉新号分流的?

(来源:中国证券报)

东方甄选净利润大幅下滑

资讯

看新东方创始人俞敏洪如何回应董宇辉新号分流的?

(来源:中国证券报)

东方甄选净利润大幅下滑

资讯

-

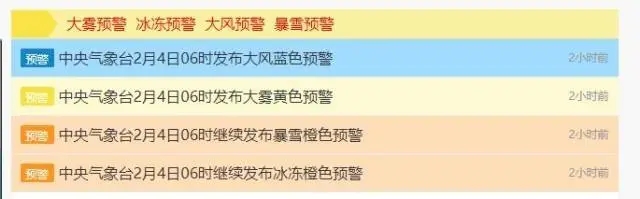

中央气象台连发四则气象灾害预警

暴雪橙色预警+冰冻橙色预警+大雾黄色预警+

资讯

中央气象台连发四则气象灾害预警

暴雪橙色预警+冰冻橙色预警+大雾黄色预警+

资讯

-

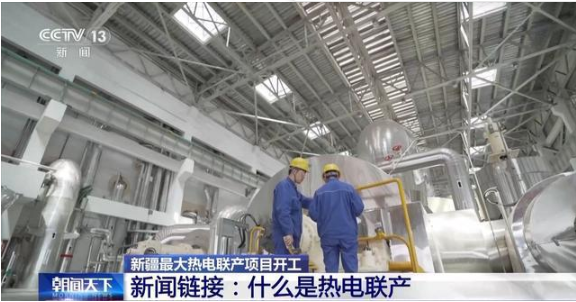

新增供热能力3200万平方米 新疆最大热电联产项目开工

昨天(26日),新疆最大的热电联产项目—&md

资讯

新增供热能力3200万平方米 新疆最大热电联产项目开工

昨天(26日),新疆最大的热电联产项目—&md

资讯

-

王自如被强制执行3383万

据中国执行信息公开网消息,近期,王自如新增一

资讯

王自如被强制执行3383万

据中国执行信息公开网消息,近期,王自如新增一

资讯

-

男子“机闹”后航班取消,同机旅客准备集体起诉

1月4日,一男子大闹飞机致航班取消的新闻登上

资讯

男子“机闹”后航班取消,同机旅客准备集体起诉

1月4日,一男子大闹飞机致航班取消的新闻登上

资讯

-

奥运冠军刘翔更新社交账号晒出近照 时隔473天更新动态!

2月20日凌晨2点,奥运冠军刘翔更新社交账号晒

资讯

奥运冠军刘翔更新社交账号晒出近照 时隔473天更新动态!

2月20日凌晨2点,奥运冠军刘翔更新社交账号晒

资讯

-

海南大学生返校机票贵 有什么好的解决办法吗?

近日,有网友在“人民网领导留言板&rdqu

资讯

海南大学生返校机票贵 有什么好的解决办法吗?

近日,有网友在“人民网领导留言板&rdqu

资讯