The Ultimate Guide to Choosing Carbon Fiber Sheets for Your Next Custom Project

When it comes to selecting materials for custom projects, Carbon Fiber is often the material of choice for industries seeking strength, lightweight properties, and superior durability. From aerospace and automotive applications to sports equipment and industrial components, Carbon Fiber Sheets offer an unparalleled combination of performance and versatility. In this ultimate guide, we'll help you navigate the key considerations when choosing the perfect Carbon fiber sheets for your next custom project.

Why Choose Carbon Fiber Sheets?

Before diving into the details, let’s first explore why carbon fiber is the material of choice for many high-performance applications:

-

Strength-to-Weight Ratio: Carbon fiber is renowned for its ability to provide immense strength while being significantly lighter than traditional materials like steel and aluminum. This makes it ideal for applications where reducing weight without compromising strength is critical.

-

Durability and Longevity: Carbon fiber is resistant to fatigue, corrosion, and wear, making it suitable for environments where materials are exposed to extreme conditions. This leads to longer-lasting components with reduced maintenance needs.

-

Heat Resistance: Carbon fiber can withstand high temperatures, maintaining its properties even in environments that would degrade metals and plastics. This makes it a key material in aerospace, automotive, and high-performance industries.

-

Customization: Carbon fiber sheets can be tailored to meet the exact specifications of your project, including thickness, size, finish, and weave pattern. This flexibility makes carbon fiber ideal for both large-scale industrial designs and smaller, more specialized projects.

Key Considerations When Choosing Carbon Fiber Sheets

To ensure you select the best carbon fiber sheets for your custom project, here are the most important factors to consider:

1. Application Type: Understanding Your Project’s Needs

The first step in choosing carbon fiber sheets is to understand the specific requirements of your project. Different industries may require distinct properties from carbon fiber, such as strength, flexibility, or heat resistance. Here’s a breakdown of the most common applications:

-

Aerospace: Aerospace Applications often require high-strength and Lightweight Carbon Fiber sheets for components like aircraft wings, fuselages, and interior panels. The sheets must be able to withstand extreme conditions, including high stress and temperature variations.

-

Automotive: In the automotive sector, especially for sports cars and electric vehicles, carbon fiber sheets are used to reduce vehicle weight and improve fuel efficiency without sacrificing structural integrity. They’re commonly used for body panels, chassis, and interior components.

-

Sports Equipment: From bicycles to golf clubs, fishing rods, and skis, carbon fiber is used in sports equipment for its lightweight and strong properties, enabling athletes to enhance their performance.

-

Industrial Components: Carbon fiber is also used in industrial settings, such as robotic arms, machinery components, and aerospace tooling, where strength, durability, and resistance to wear and tear are essential.

2. Material Properties: Understanding the Different Types of Carbon Fiber Sheets

Carbon fiber sheets come in a range of types, each with unique characteristics. The most important factors to consider are the weave pattern, fiber orientation, and resin type.

-

Weave Pattern: The weave of the carbon fiber determines its aesthetic appearance and can influence its strength and flexibility. Common weave patterns include:

- Plain Weave: A balanced weave that provides equal strength in both directions. It’s versatile and easy to mold.

- Twill Weave: Offers a more flexible and aesthetic finish, often used in visible parts of automotive or aerospace components.

- Unidirectional: Increases strength in one direction, often used for applications that require directional strength like reinforced beams or spars.

-

Fiber Orientation: Carbon fiber sheets can be woven or unidirectional. Woven sheets provide balanced strength in multiple directions, whereas unidirectional fibers are stronger in one direction, making them ideal for structures that experience forces in a single direction (e.g., beams and supports).

-

Resin Type: The resin used in carbon fiber sheets can impact the material’s performance. The most common resins include epoxy, vinyl ester, and polyester, with epoxy being the preferred option due to its strong bonding and heat resistance.

3. Thickness and Size: Customizing to Your Project’s Requirements

The thickness of carbon fiber sheets directly influences their strength and rigidity. For custom projects, choosing the right thickness is crucial to balance performance and weight.

- Thin Sheets: Thin carbon fiber sheets (e.g., 0.5mm to 2mm) are ideal for applications that require flexibility or where weight reduction is a priority.

- Thicker Sheets: Thicker carbon fiber sheets (e.g., 3mm to 10mm) are suitable for structural components that need added strength and rigidity. These sheets are often used in aerospace and automotive industries for parts like brackets, mounting structures, and reinforced panels.

Carbon Fiber Global offers customizable sizes and thicknesses, allowing you to select the perfect carbon fiber sheets for your project.

4. Surface Finish: Aesthetic and Functional Considerations

The finish of carbon fiber sheets is not just about aesthetics; it can also affect the material’s performance. Some common finishes include:

-

Glossy Finish: Often chosen for aesthetic purposes, a glossy finish enhances the visual appeal of Carbon Fiber Products, making them a popular choice for automotive and sports equipment.

-

Matte Finish: For applications where glare reduction or a more industrial look is required, a matte finish provides a more subtle appearance.

-

Coated Finish: A coated surface can enhance the material's resistance to abrasion or UV degradation, making it ideal for outdoor applications like marine parts or exterior aerospace components.

5. Cost vs. Performance: Balancing Budget and Quality

Carbon fiber is known for its premium cost, especially in industries that demand the highest performance. However, the material’s long-term durability and performance benefits often justify the higher upfront cost. When selecting carbon fiber sheets, it’s important to balance cost with the performance requirements of your project.

For projects with limited budgets, consider whether using thinner sheets or lower-grade resins could achieve the necessary performance without overspending.

6. Supplier Reputation: Why Carbon Fiber Global is the Best Choice

When choosing carbon fiber sheets for your custom project, selecting a reputable supplier is essential. Carbon Fiber Global stands out as an industry leader, offering:

- High-Quality Products: Our carbon fiber sheets are manufactured to the highest standards, ensuring consistent quality and performance.

- Custom Solutions: We provide tailored carbon fiber sheets to meet your unique project requirements, whether you're in aerospace, automotive, or another industry.

- Expert Guidance: Our team of experts is here to help you select the perfect materials, from choosing the right resin to determining the best weave pattern and thickness for your needs.

Conclusion: Make Your Next Custom Project a Success with Carbon Fiber Sheets

Selecting the right carbon fiber sheets for your custom project is a critical step in ensuring the success of your application. By considering factors such as application type, material properties, thickness, finish, and supplier reputation, you can make an informed decision that enhances the performance, durability, and efficiency of your project.

At Carbon Fiber Global, we are committed to providing premium Carbon Fiber Solutions tailored to your specific needs. Whether you’re working on an aerospace design, automotive prototype, or sports equipment innovation, our team is here to support you every step of the way. Contact us today to learn more about how our carbon fiber sheets can bring your next custom project to life.

- 做法简单的家常菜,营养美味又下饭

- 内蒙古福寿园“书情画意福寿延年”主题书画笔会成功举办

- 解锁乡村美味,农副食品电商带你品味纯正大自然

- 春华秋实二十载 inter airport China 20年见证机场业之腾飞

- 海之盛宴:探索海洋宝藏,品味海产品平台的无尽魅力

- 《让影响力的人物载入》中医领军人物张培轩先生隆重报道

- XCS20XL-4VQG100C: Enabling Compact and Efficient FPGA Solutions | ChipsX

- 北京古今胜国际拍卖客户精品藏品展示-《大明宣德青花莲花纹玉壶春瓶》GJSCP-CQ009

- 中国数贸携手精品消费月,开启全民交易新体验

- 越捷航空进一步提高机队运力,满足农历新年假期日益增长的旅游需求

推荐

-

APP未经同意跳转广告涉嫌违法!规定至少转动35°、3秒以上才能跳转

打开APP,广告立刻占满屏幕;不小心稍稍碰到屏

生活

APP未经同意跳转广告涉嫌违法!规定至少转动35°、3秒以上才能跳转

打开APP,广告立刻占满屏幕;不小心稍稍碰到屏

生活

-

娱乐圈消息:张彬彬代旭携刘敏涛立牌宣传新剧

4月7日,张彬彬、代旭领衔主演,刘敏涛、袁姗姗

生活

娱乐圈消息:张彬彬代旭携刘敏涛立牌宣传新剧

4月7日,张彬彬、代旭领衔主演,刘敏涛、袁姗姗

生活

-

方媛晒全家福为57岁郭富城庆生,夫妻俩搂腰合影,女儿们甜美可爱

10月26日11点58分,方媛赶在夜深人静的时候,低

生活

方媛晒全家福为57岁郭富城庆生,夫妻俩搂腰合影,女儿们甜美可爱

10月26日11点58分,方媛赶在夜深人静的时候,低

生活

-

女神张钧甯大方认爱大马导演柯汶利!传拍《唐人街探案》擦出爱火!

台湾女神张钧甯一向被视为华语影坛的「黄金

生活

女神张钧甯大方认爱大马导演柯汶利!传拍《唐人街探案》擦出爱火!

台湾女神张钧甯一向被视为华语影坛的「黄金

生活

-

世人皆知王阳明格竹七日七夜而不得圣人之理

世人皆知王阳明格竹七日七夜而不得圣人之

生活

世人皆知王阳明格竹七日七夜而不得圣人之理

世人皆知王阳明格竹七日七夜而不得圣人之

生活

-

今年内“喜”的3D复原像将在湖北省博物馆通史展厅展出

相貌端正、身材匀称、有点“职业病”……湖

生活

今年内“喜”的3D复原像将在湖北省博物馆通史展厅展出

相貌端正、身材匀称、有点“职业病”……湖

生活

-

在游客猛增的情况下,“进岛不易出岛难”问题受到关注

2024年春节假期,海南再次成为国内最热门的旅

生活

在游客猛增的情况下,“进岛不易出岛难”问题受到关注

2024年春节假期,海南再次成为国内最热门的旅

生活

-

画家笔下时代的悲喜剧被展览简化为一条“连衣裙”?

2月22日,展览“萨金特与时尚”在

生活

画家笔下时代的悲喜剧被展览简化为一条“连衣裙”?

2月22日,展览“萨金特与时尚”在

生活

-

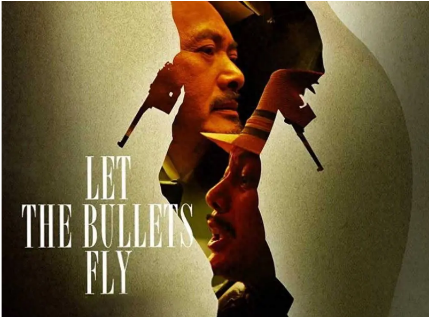

姜文电影《让子弹飞》让很多人认识了传奇作家马识途

2024年3月28日,革命家、作家、书法家马识途

生活

姜文电影《让子弹飞》让很多人认识了传奇作家马识途

2024年3月28日,革命家、作家、书法家马识途

生活

-

你可知道韩国国民心目中此生必来的一个地方是哪儿吗?

距离韩国首尔约1800公里的张家界,是如何成为

生活

你可知道韩国国民心目中此生必来的一个地方是哪儿吗?

距离韩国首尔约1800公里的张家界,是如何成为

生活